PCB Fabrication

1. Traces

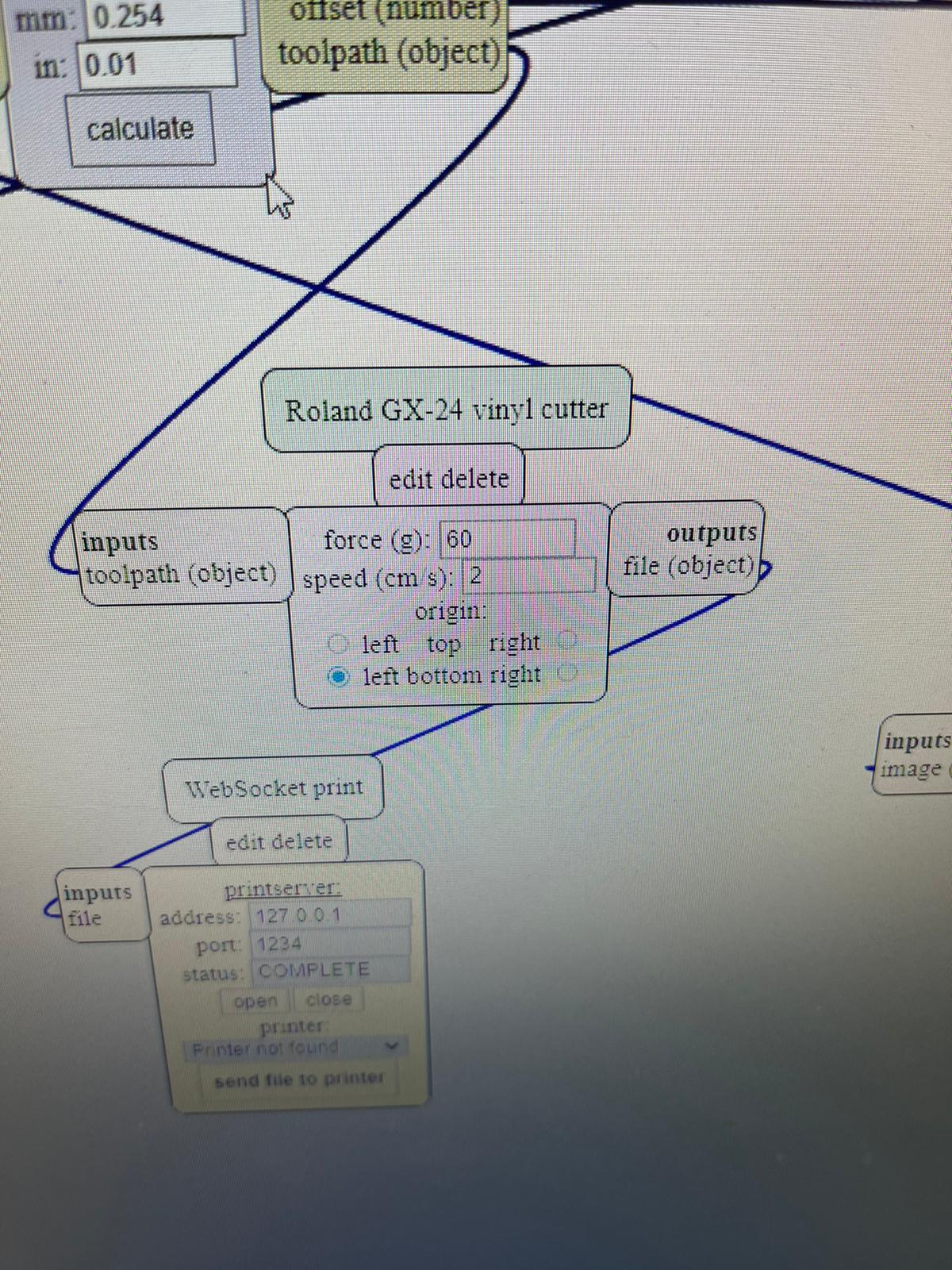

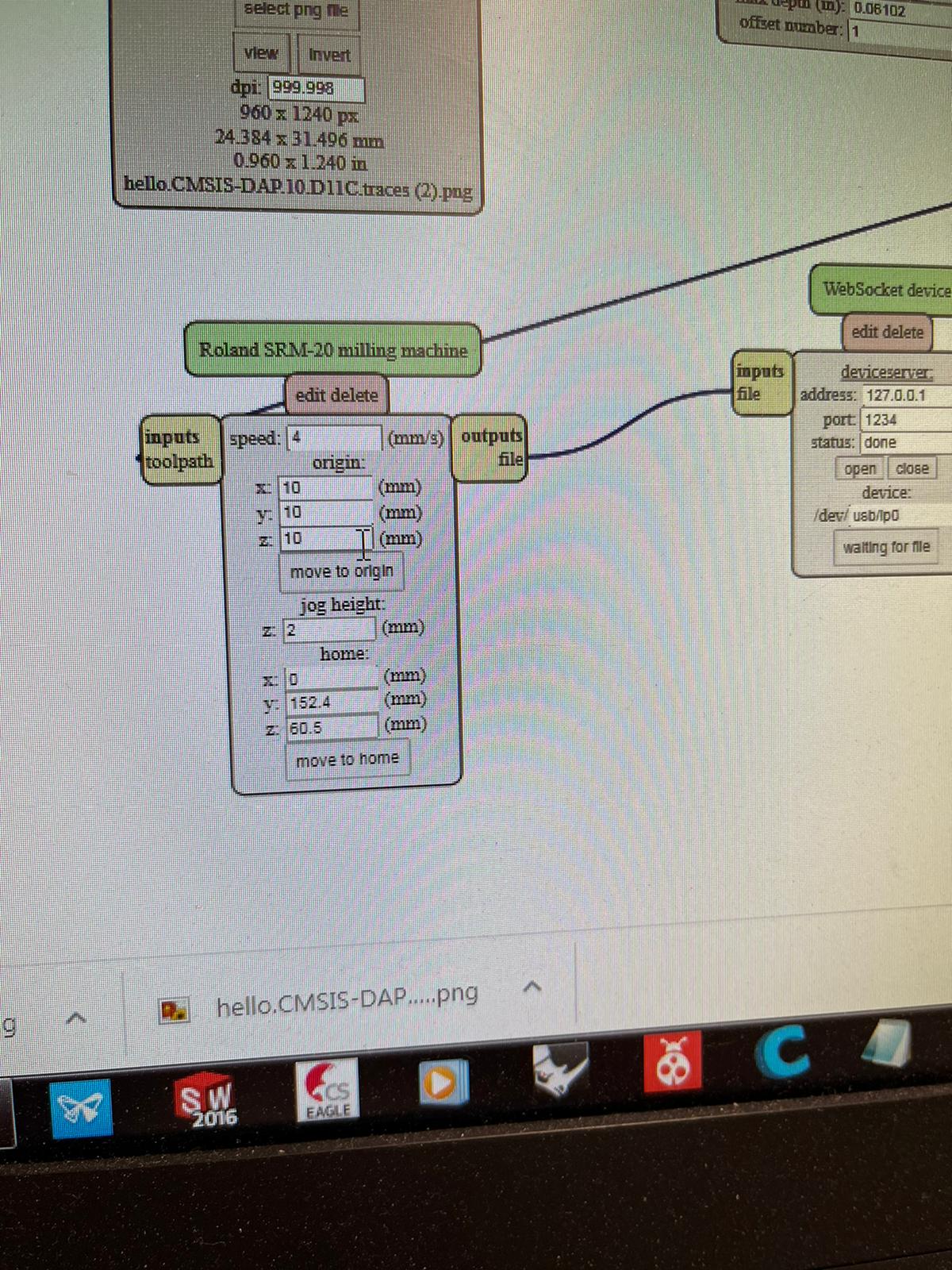

a. Setting Up Mods

I was really excited for this week because I had always wanted to learn about PCB creation. The machine was pretty similar to the laser cutter that we had used last week, but instead of a laser it was using a fast spinning drill bit.

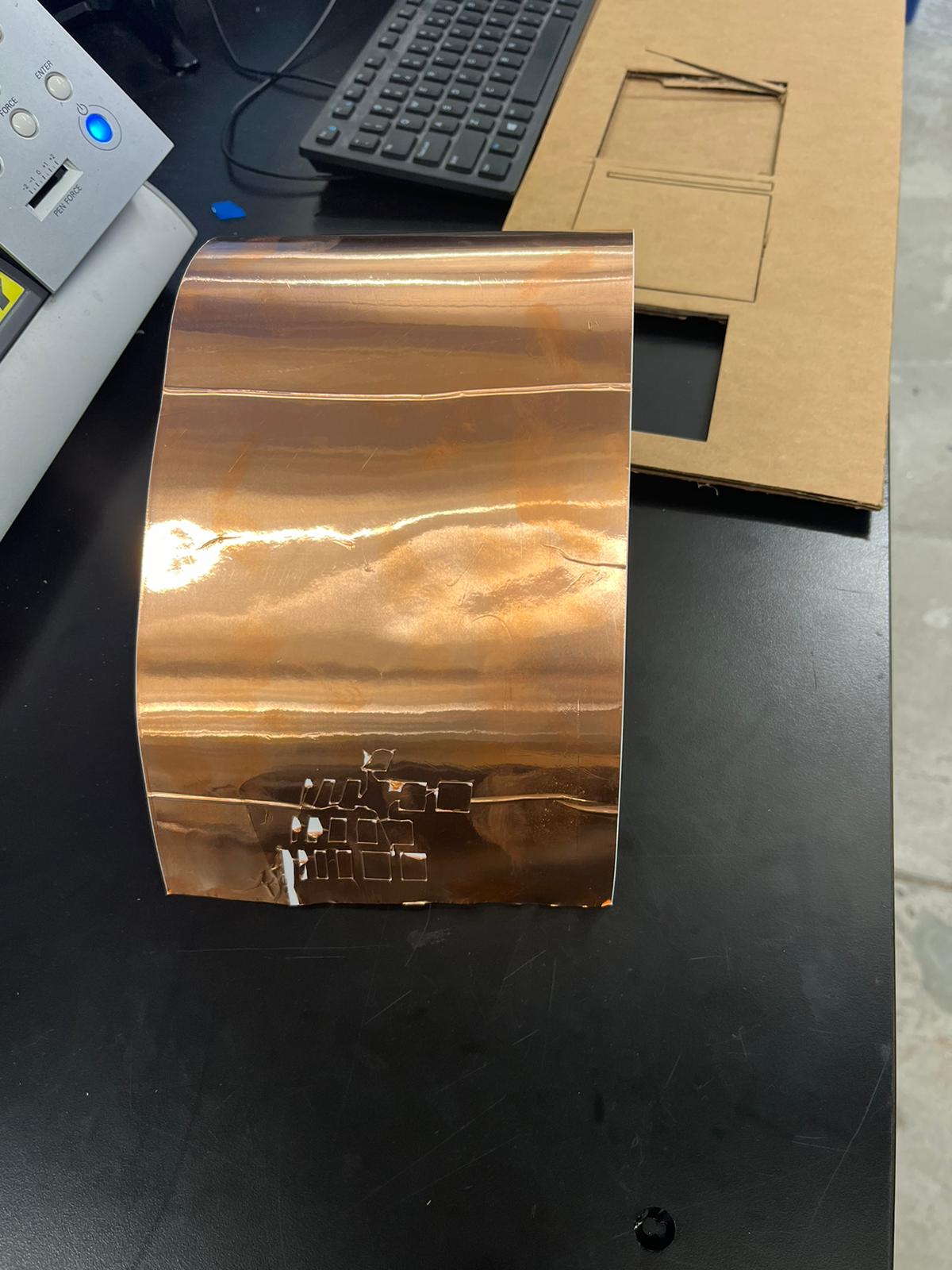

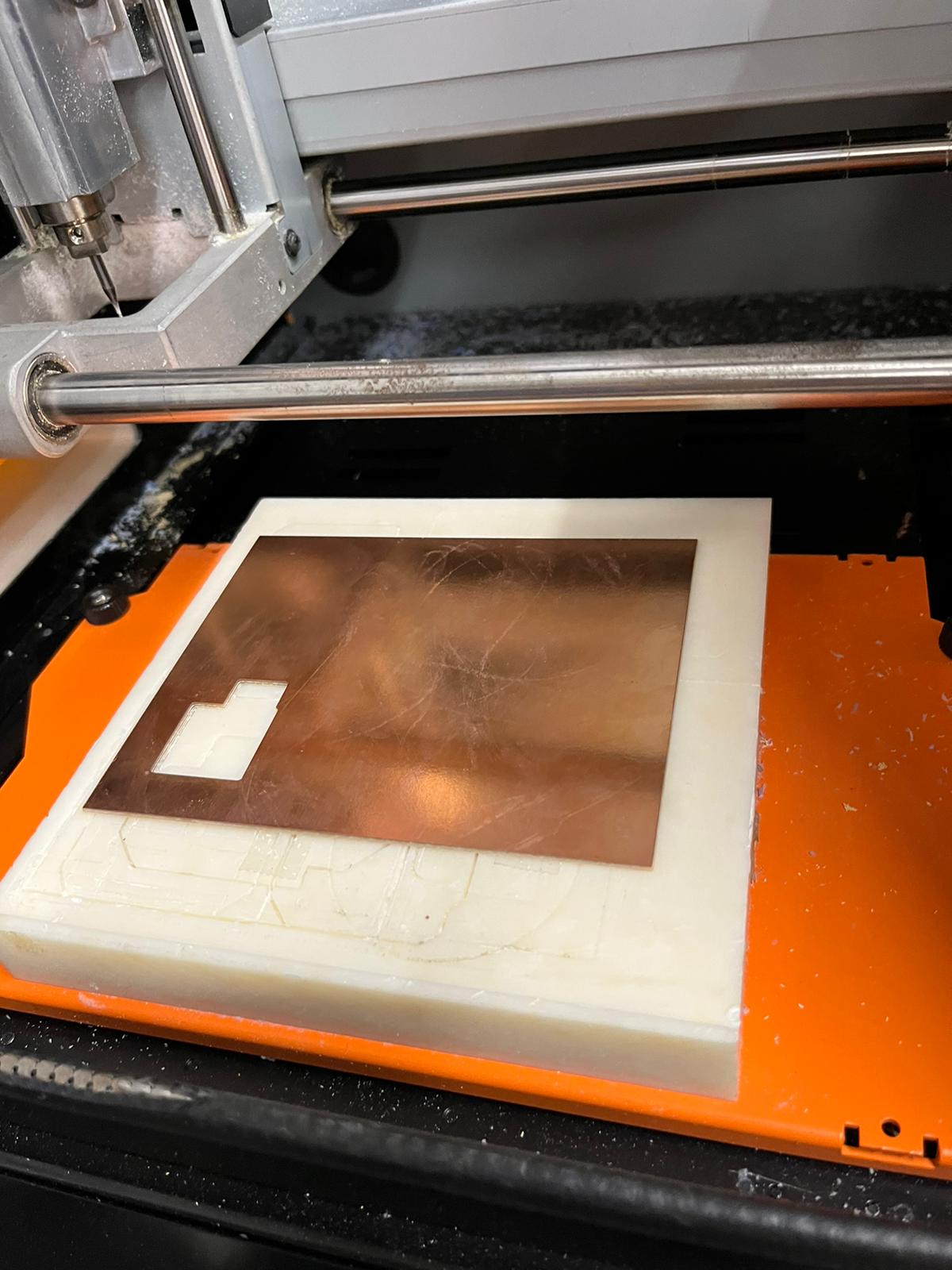

b. Taping Board

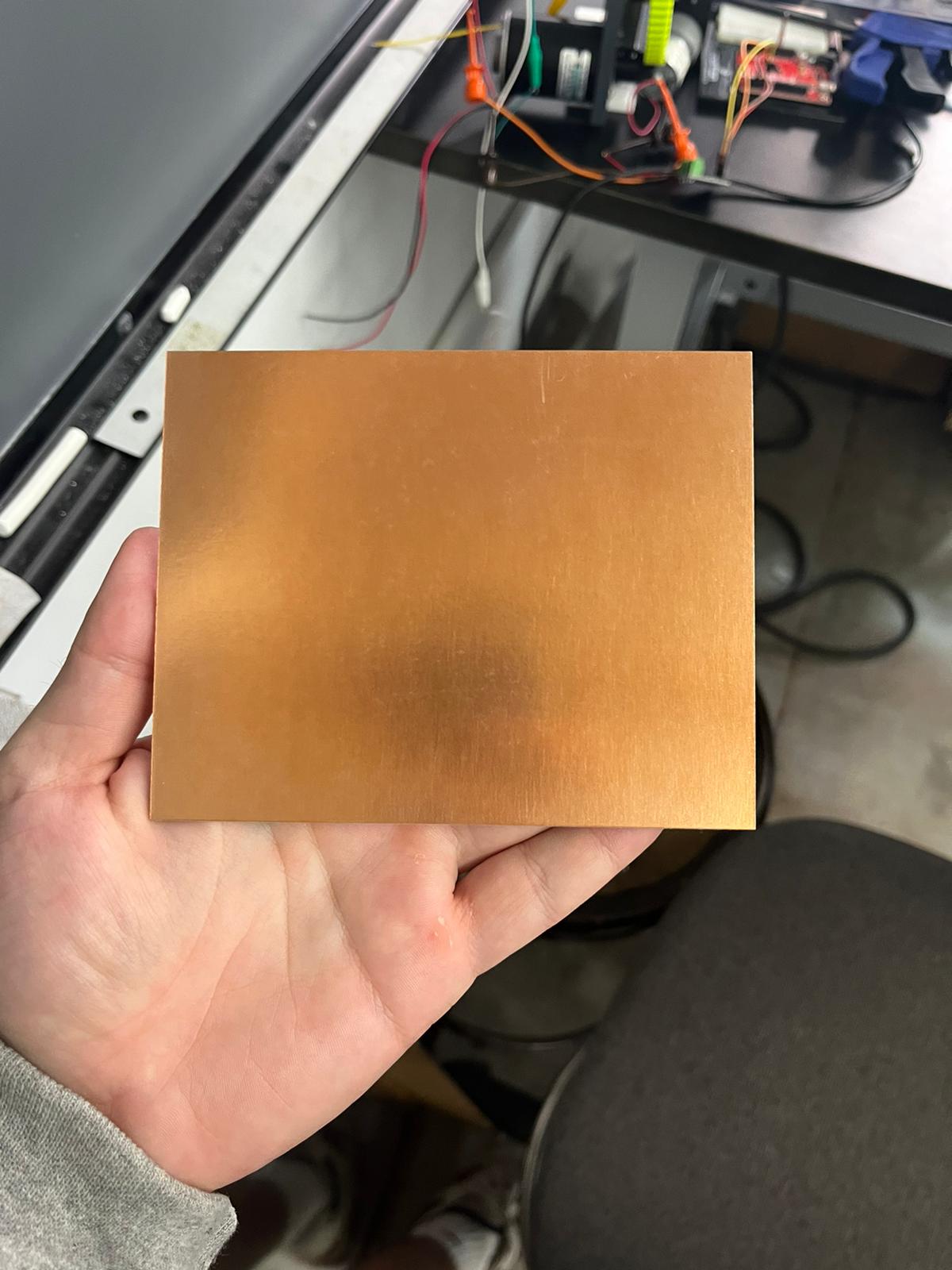

The boards themselves are copper on top and phenolic paper on the bottom.

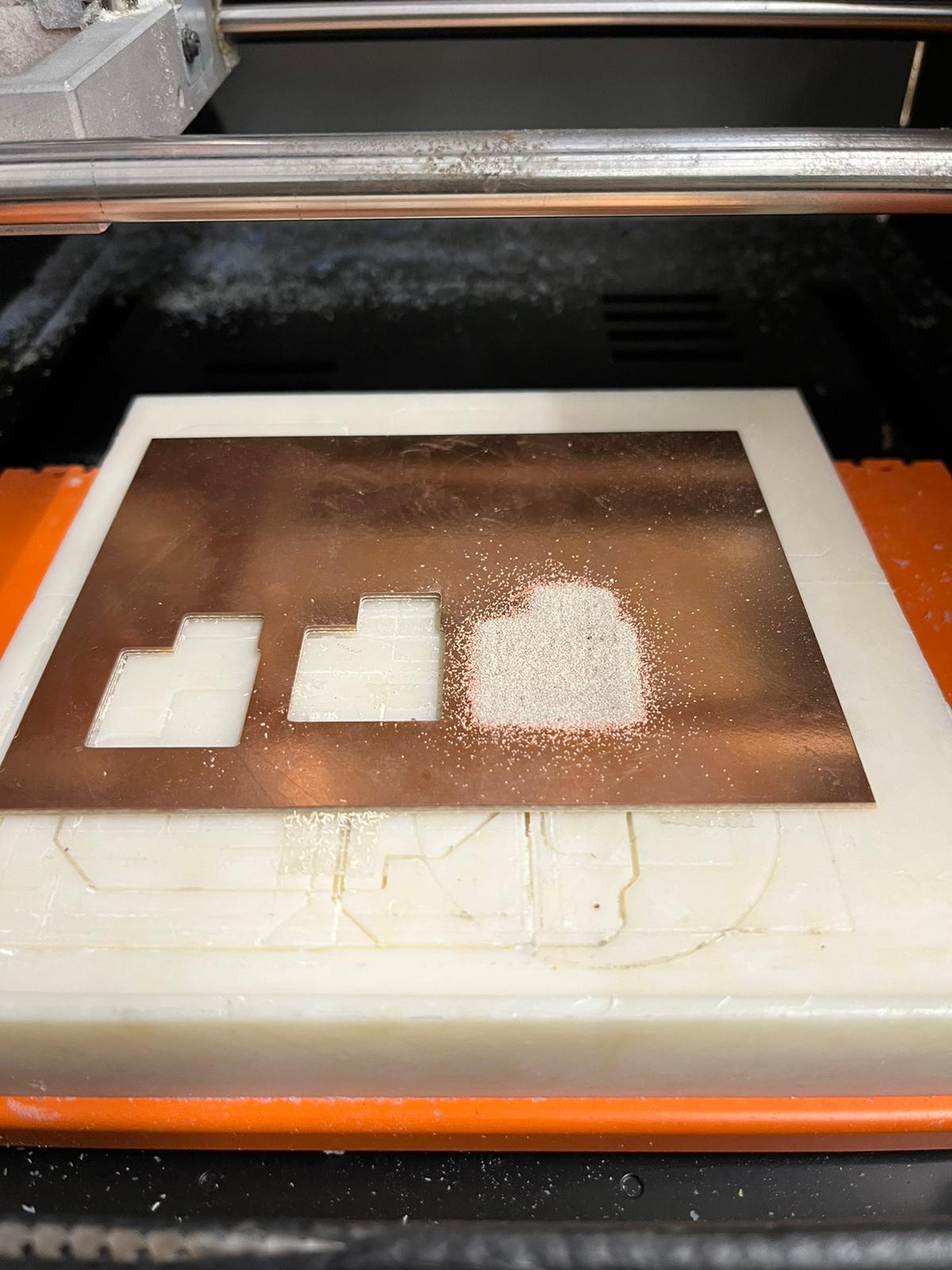

c. Cutting the Board

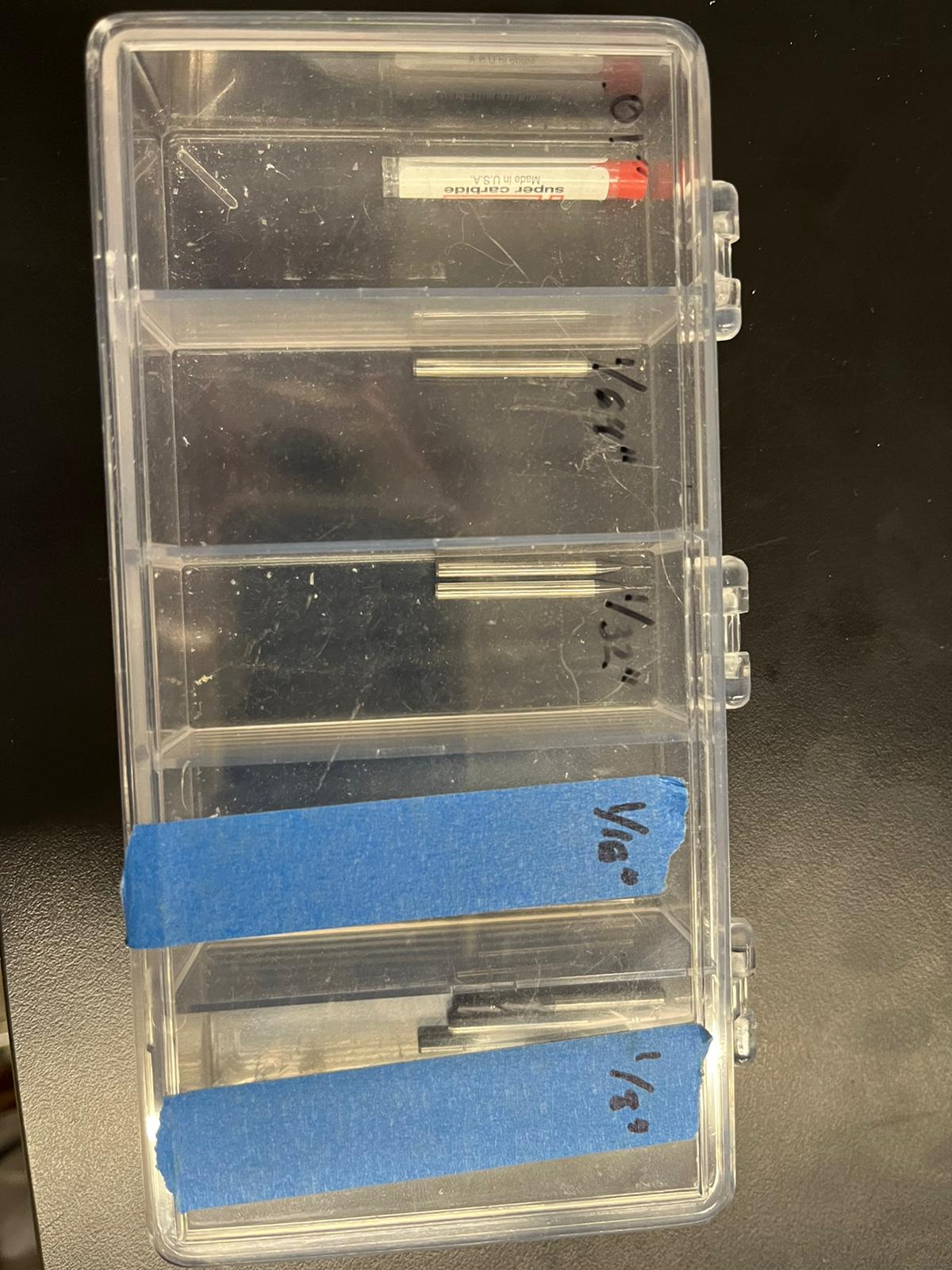

To start I changed had to change the drill bit to the 1/64 inch bit, I did that by unscrewing using a hex wrench. Then I started adjusting the origin in order to drill in the correct place. I needed to play around with mods to find the best place to drill.

2. Soldering

I came in confident about the soldering but as I started on the board I realized how much I didn't know. I had only soldered on larger electronics and did not realize the problems I would run into when I started with the smaller board. The first problem was the solder I was using. I was using the larger solder instead of the thinner one.

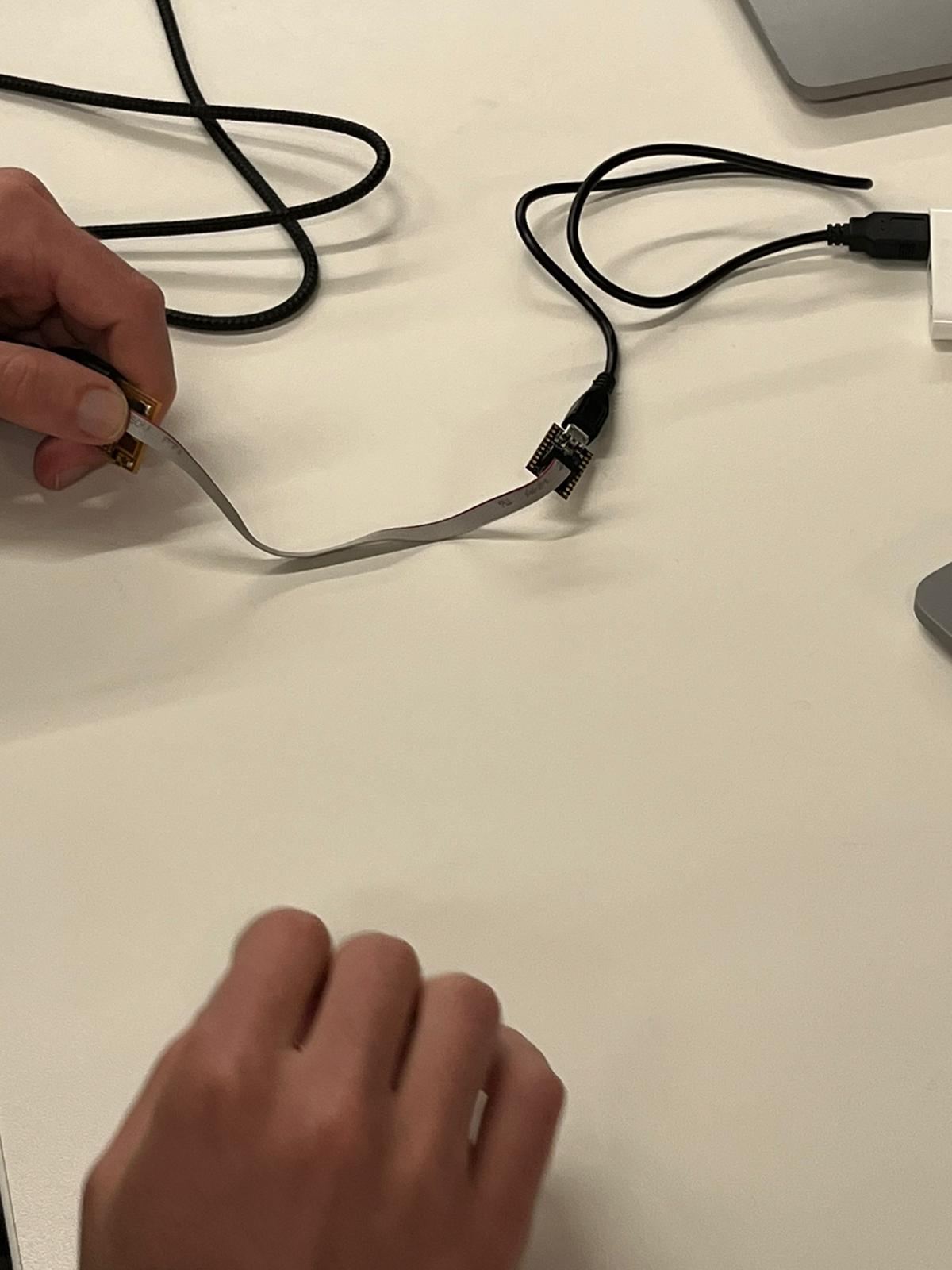

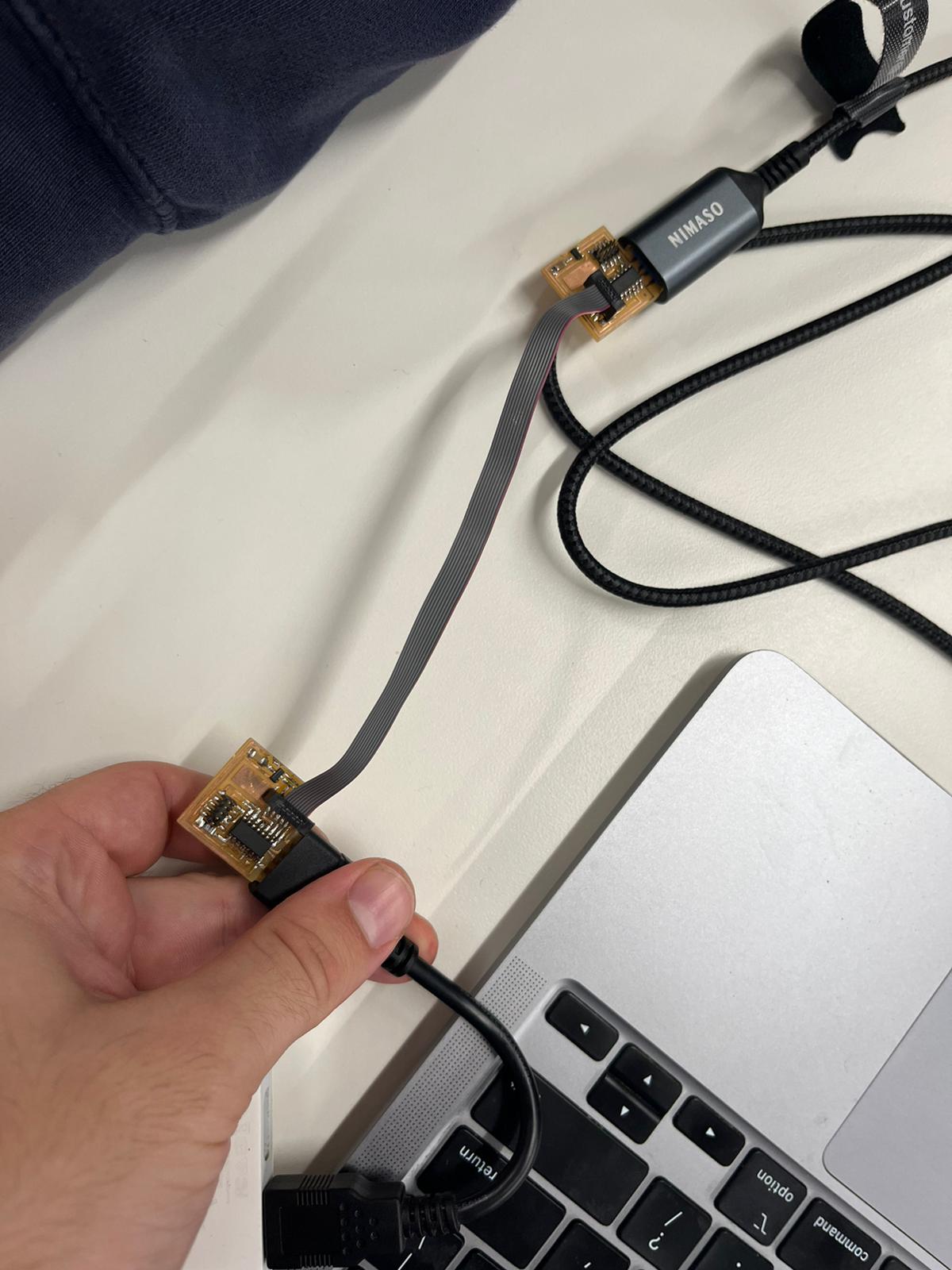

3. Programming

I was most excited about this part because I really wanted to work with embedded devices when I was looking at the class. Leo describing the way the programmer works and why we were learning this had me excstatic. I had never used a bootloader before and so it took a little time to get all of it downloaded. Leo had to help give us the binary because we were having a hard time using openocd. How many people does it take to program one board? In our case it took four students and one TF. When we were trying to program the board we ran into many errors about bad connections, old computers and many different PCBs.

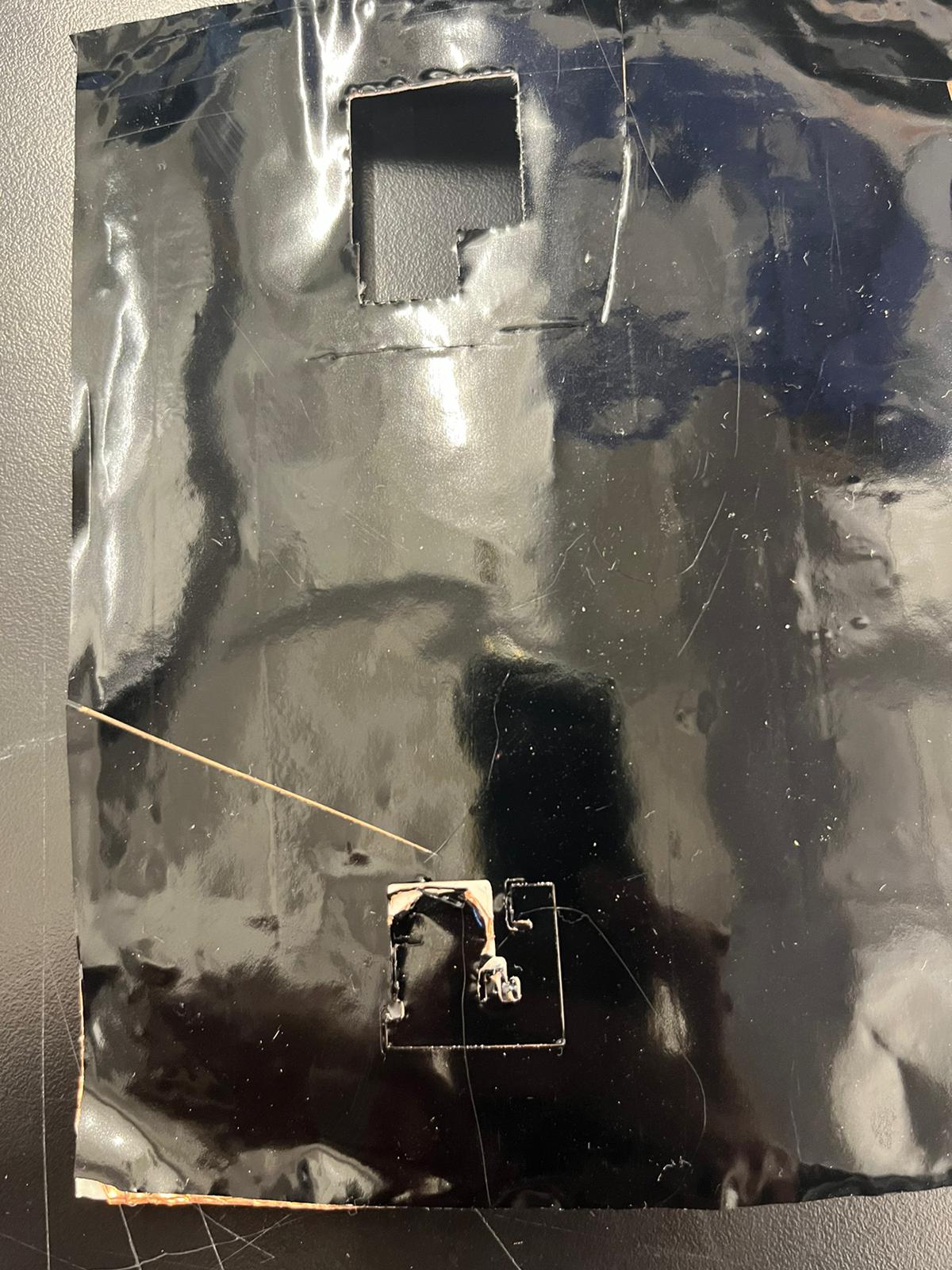

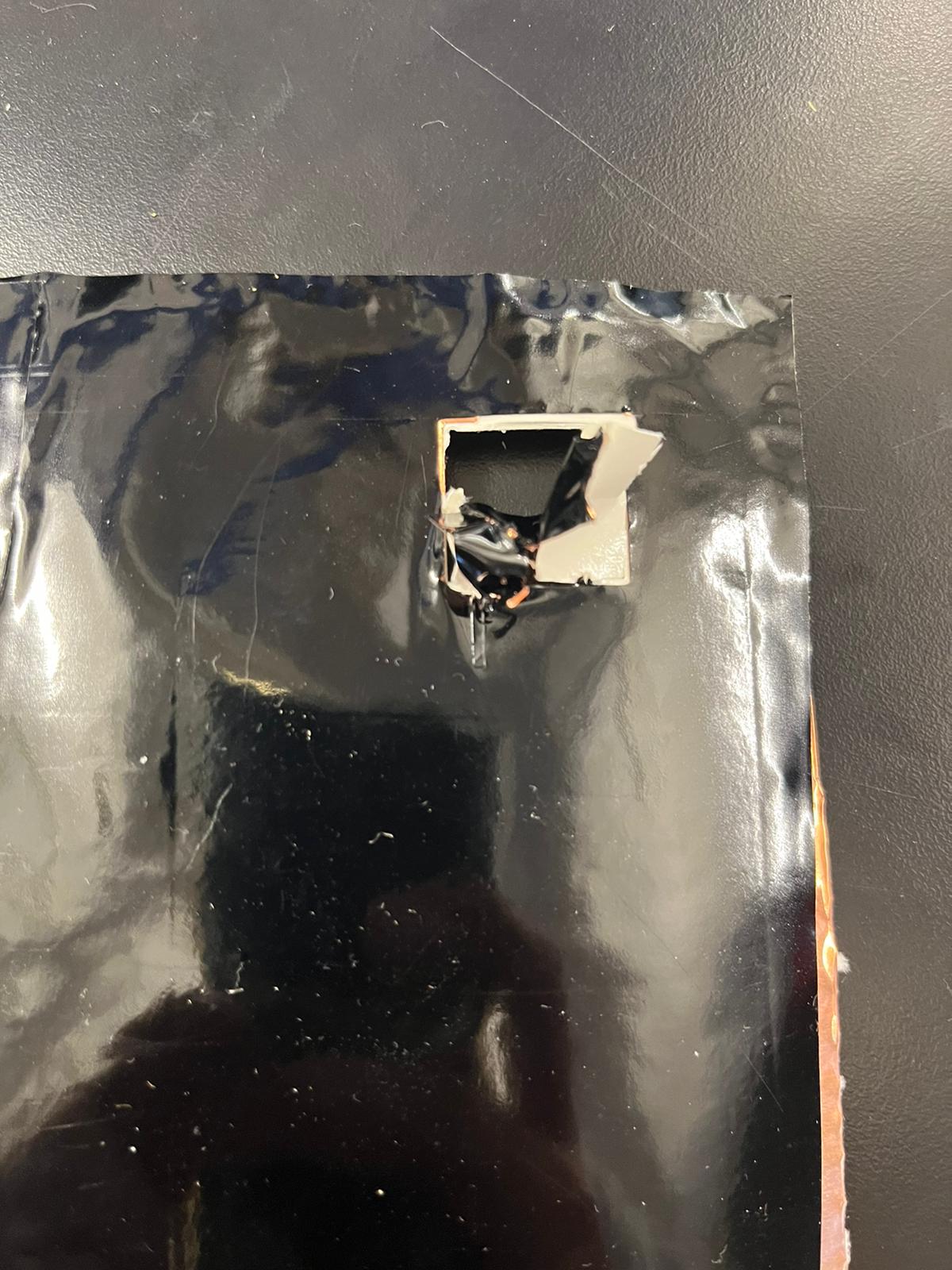

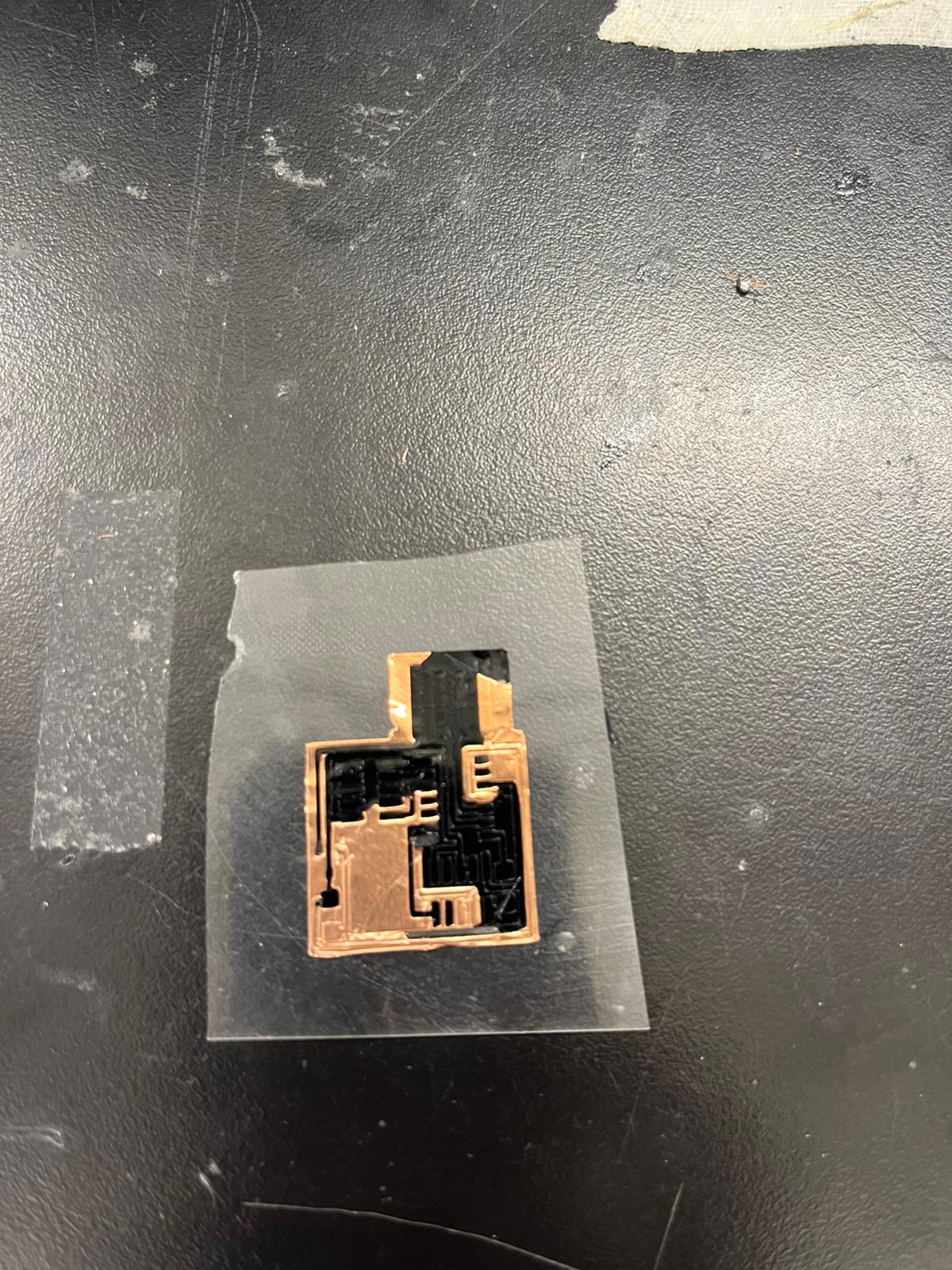

4. Vinyl Cutting

After finishing the initial project I wanted to try to use the vinyl cutter to redo the project. I feel like I have many ideas that require flexible circuit boards. I remembered Prof Neil talking about sticking another sticky substance to the top and then pulling off on the desired surface. I definelty did not remember correctly. The TF I was working with also didn't know 100% so I ended up with failures like these.